Blog de Automação

Automatização adaptada para embalagens sustentáveis

16 de agosto de 2022 Alguma vez encomendou um pequeno artigo online e sentiu-se incomodado quando este chegou numa caixa de grandes dimensões com plástico de bolhas, almofadas de ar ou envelopes de papel?

Exposição itinerante sobre fabrico flexível: levar a fábrica do futuro a toda a Europa

16 de junho de 2022 E se pudesse ver, sentir e entrar em contacto com a fábrica do futuro? O que é necessário para alcançar uma produção flexível, eficiente e sustentável? Estas são as questões na base da exposição itinerante sobre fabrico flexível da OMRON, que viaja pela Europa este ano. A exposição itinerante inclui demonstrações exclusivas de soluções colaborativas entre seres humanos e máquinas, que normalmente não são observadas fora de fábricas devido à respetiva dimensão e escala.

Construir a fábrica do futuro em conjunto

16 de junho de 2022 Na qualidade de uma das maiores unidades de negócio da OMRON, pretendemos continuar a desenvolver a fábrica em Den Bosch para responder às necessidades na região EMEA.

Rastreabilidade no setor automóvel: o que os responsáveis pela tomada de decisões e especialistas devem procurar agora

23 de maio de 2022 Da mobilidade elétrica à condução autónoma, da escassez de competências à digitalização: a indústria automóvel está a sofrer uma profunda mudança marcada, por exemplo, pela mudança para plataformas globalizadas e arquiteturas de veículos padronizadas. Por um lado, a produção está a tornar-se cada vez mais eficiente, mas, por outro lado, uma única peça defeituosa pode ter efeitos mais extensivos do que nunca. Confrontados com retiradas dispendiosas de produtos, os fabricantes na indústria automóvel enfrentam requisitos cada vez mais complexos e especificações mais rigorosas. Será que vale a pena o esforço de rastreabilidade se isto significa etiquetar até 20 000 peças por veículo? Sim, vale a pena, mas é necessário um software potente, combinado com tecnologias potentes de leitura e verificação, para os dados fazerem sentido.Existem várias razões pelas quais os fabricantes precisam de manter registos precisos das peças e componentes que constituem um automóvel novo. Do ponto de vista da qualidade, por exemplo, a rastreabilidade através de códigos de barras ajuda a garantir que são montadas as peças corretas. Mais importante ainda é, contudo, a capacidade de rastrear o fornecedor original de cada peça do automóvel. Em caso de retirada de produtos ou de descoberta de uma peça defeituosa, os fabricantes têm de ser capazes de descobrir a origem de cada peça de forma rápida e abrangente. Isto é complementado por informações como o número do lote, a data de fabrico e outras informações importantes para identificar quais os veículos afetados pela peça defeituosa. Recomendações e padrões da AIAG, VDA, ANSI e ISO especificam os detalhes. À medida que a indústria automóvel se globaliza, espera-se que a produção mundial de veículos ligeiros atinja cerca de 96 milhões de unidades até 2023. Isto significa que mesmo uma única peça defeituosa pode ter um enorme impacto, pelo que deve ser evitada a todo o custo.

Ausência de intervenção humana? Ainda pouco provável com a Indústria 4.0

21 de abril de 2022 Para muitos fabricantes, a perspetiva de uma fábrica totalmente automatizada e livre de seres humanos parece estar à distância de muitos anos. Estes questionam-se: quando chegará a 4.ª revolução industrial e o que podemos esperar? Nesta publicação, analisamos a realidade da produção (totalmente/semi) automatizada, o que os robôs podem e não podem fazer e por que razão a ação humana ainda é (maioritariamente) insubstituível.

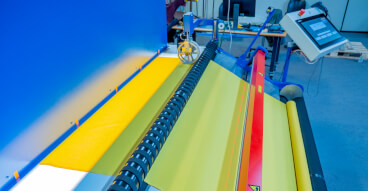

Vadain automatiza a inspeção de tecidos para cortinas com visão da máquina

08 de abril de 2022 A Vadain, líder de mercado em cortinas personalizadas nos Países Baixos, necessitou de uma solução para detetar erros o mais antecipadamente possível em quilómetros de tecido para cortinas. Juntamente com os programadores de software da Sycade, a tecnologia de visão da máquina da OMRON e o fabricante de máquinas Eisenkolb, desenvolveram uma solução automatizada para detetar e analisar erros em tecidos para cortinas, eliminando o moroso processo de inspeção manual.

As fábricas tradicionais também necessitam de dados

18 de março de 2022 As ferramentas e tecnologias certas podem permitir uma manutenção preventiva avançada, prevenção de constrangimentos e otimização. Descubra de que forma a digitalização colmata a lacuna entre os sistemas antigos e a Indústria 4.0.

Combustível para o futuro: o que procurar na produção de células de combustível

10 de março de 2022 Quando se fala sobre mobilidade sustentável, a primeira coisa em que se pensa é em carros elétricos a bateria. Células de combustível ou queimadores diretos de hidrogénio consistem em tecnologias complementares que muitas vezes ficam em segundo plano, mas têm muito a oferecer relativamente à redução de CO₂ e opções de mercado.

Enfrentar os desafios da embalagem e da intralogística no comércio eletrónico

24 de fevereiro de 2022 A embalagem assistida por robôs permite uma expansibilidade rápida e económica, para cima e para baixo, de modo a lidar com variações nas exigências da cadeia de fornecimento.

Indústria de embalagens ecológicas: como alcançar um fabrico sustentável

09 de fevereiro de 2022 A sustentabilidade na indústria de embalagens é um dos principais aspetos no combate ao problema dos resíduos plásticos e, em última análise, às alterações climáticas. Os desafios que apresenta requerem uma tecnologia de automação flexível e potente.

Hanover Displays automatiza testes de PCBA com cobôs

31 de janeiro de 2022 A Hanover Displays Limited, sedeada no Reino Unido, necessitava de um novo sistema para testar conjuntos de placas de circuito impresso (PCBA) e, para tal, selecionou os cobôs da série TM da OMRON, fornecidos e instalados pela Absolute Robotics, parte da Absolute Automation Group.

Cinco desafios nos processos de embalagem e paletização de mistura elevada e baixo volume (HMLV)

21 de dezembro de 2021 O novo produto acaba de sair da fábrica, numa embalagem pronta para a prateleira na proporção de variação especificada para satisfazer as necessidades do cliente. A embalagem foi efetivamente tratada por outra empresa: um local de co-embalagem. A co-embalagem pode ser encontrada em todos os mercados de bens de grande consumo (FMCG), mas especialmente nos segmentos de produtos de custo mais elevado, tais como cuidados pessoais ou produtos de confeitaria, por exemplo. É uma atividade crescente para satisfazer a procura do consumidor por mais variedade.

Escolher um robô para uma fábrica inteligente

02 de abril de 2021 Se pretende avançar em direcção a uma fábrica inteligente, deve considerar e escolher cuidadosamente as possíveis soluções robóticas. Qual se adequa melhor: um robô industrial ou um robô colaborativo (cobô)? Um robô móvel autónomo (AMR) ou um conjunto de braço robótico de montagem fixa com flexibilidade selectiva (SCARA)? A resposta dependerá das suas necessidades específicas.

Cobot Dashboard: How to visualize data for OEE improvement the smart way

16 de março de 2021 The factory of the future is not only based on a well-orchestrated interaction of the most diverse machines, robots, sensors, and AI technologies. Entrepreneurs and decision-makers are also increasingly faced with the challenge of reconciling the vast amounts of data collected by the various production lines and making the best possible use of it to support their decisions. Not only does a comprehensive data strategy need to be developed. There are also technologies required that process and present the data in such a way that issues are immediately identified before major problems occur.

Automação para um sistema "sem toque": aumentar a segurança, a qualidade e a eficiência no sector da alimentação e bebidas

15 de março de 2021 As recentes inovações em automação, robótica, processamento de imagem e inteligência artificial (IA) podem ajudar as empresas a migrar para um sistema de processamento "sem toque".

Robô móvel transporta resíduos para o Hospital Central de Kymenlaakso, na Finlândia

08 de março de 2021 O transporte de resíduos e o planeamento logístico requerem muito trabalho em ambientes hospitalares. A transferência de resíduos é também uma tarefa física que exige tempo e recursos humanos.

Automação acessível: leasing de cobôs e os robôs móveis para flexibilidade na fábrica

04 de março de 2021 A par da mudança para a Indústria 4.0, um número crescente de fabricantes está a aderir à automação como forma de simplificar os processos e aumentar a produtividade. Um aspecto fundamental desta solução é a utilização de robôs que trabalham, muitas vezes, em conjunto com as pessoas na fábrica. No entanto, muitas empresas ainda podem estar reticentes quanto ao investimento em automação adicional, especialmente devido às dificuldades económicas causadas pela COVID-19. Para os fabricantes que procuram uma solução acessível, estão a ser implementadas estruturas de custos com opções de leasing como uma opção para permitir a adaptabilidade na fábrica.

Inovadora aplicação de cobot aumenta segurança na Leica GeoSystems

11 de fevereiro de 2021 Robô colaborativo automatiza manuseamento de tabuleiros e aumenta segurança e ergonomia numa área de trabalho perigosa.

Desenvolvimento de produção inteligente e flexível: universidade norueguesa cria novo laboratório de fabrico repleto de robôs

10 de fevereiro de 2021 A universidade norueguesa de ciência e tecnologias (NTNU) desenvolveu um novo laboratório educativo em Ålesund para facilitar a aprendizagem e alargar a implementação da automação e robótica entre os fabricantes da região. O laboratório está equipado com uma vasta variedade de soluções da OMRON, tanto de hardware como de software.

Quatro dicas essenciais para projectos de automação na indústria da alimentação e bebidas

29 de janeiro de 2021 Um desafio acelerado pela pandemia de covid-19 tem forçado os produtores a lidarem, simultaneamente, com a proliferação da variedade a longo prazo centrada nas exigências dos consumidores e com a redução da variedade (as SKU) causada pela rápida mudança dos hábitos de consumo dos revendedores e consumidores. As empresas que abrem novos caminhos servindo-se de tecnologias inovadoras não só ganham agilidade, como também reduzem o desperdício, risco de contaminação, resíduos e perdas.

Impulsionar a indústria automóvel europeia

29 de janeiro de 2021 A indústria automóvel europeia enfrenta uma forte concorrência por parte da Ásia, bem como os desafios económicos da pandemia. É necessário que se desenvolvam estratégias e tecnologias inovadoras e à prova do futuro que aumentem a eficiência e a sustentabilidade. Tony Seba, da Universidade de Stanford, acredita que em 2025 já não serão vendidos veículos novos com motores de combustão (pura) e que haverá uma transição para automóveis a bateria ou células de combustível a hidrogénio. Entretanto, a indústria enfrenta uma queda nas vendas, regulamentos de emissões cada vez mais rigorosos, novas tecnologias, digitalização e necessidades dos consumidores em constante mudança. As empresas devem responder convertendo as linhas de produção, tornando-se mais ágeis e introduzindo inovações que proporcionem uma vantagem competitiva.

ControlTec ajuda hospital polaco a enfrentar a pandemia com robô móvel UVC

26 de janeiro de 2021 Com recurso a um robô móvel OMRON LD, a ControlTec foi uma das primeiras empresas do mundo a desenvolver um robô de esterilização equipado com um irradiador UVC.

Transporte rápido e seguro no piso da fábrica

18 de janeiro de 2021 Eficiência melhorada e fornecimento contínuo de material: na Áustria, a Philips está a automatizar o transporte de materiais, utilizando AMR da OMRON.

Integrated data control, motion control and machine vision for next-generation automotive production line

24 de abril de 2020 The Mexican regional headquarters of a leading manufacturer of premium air brake actuators for global on-highway and specialty markets required a new automated production assembly line. One of the company’s key performance indicators is to deliver a fully assembled product every 30 seconds, and it is with this end goal at the forefront that the team started the process of automating the production line.

IoT security for manufacturers

11 de dezembro de 2019 The Internet of Things (IoT) is a recent concept, involving the connection of devices that incorporate electronics, software or sensors, with the aim of collecting and exchanging data.

Smart machines: laying the golden egg?

16 de outubro de 2019 Greater manufacturing efficiency: it’s the golden egg we’re all looking for. But it’s getting increasingly hard to find. The solution could be smarter automation, which involves lots and lots of data (‘big data’) and data collection and data-driven modelling. The smart machine then uses the models to automatically adjust its own behaviour (i.e. machine learning).

A practical illustration of IoT and Industry 4.0

01 de outubro de 2019 The Internet of Things (IoT) is a relatively new phenomenon. Prof Dr Thomas Pospiech, a teacher of Production and Process Management at Heilbronn University of Applied Sciences, was interviewed recently about the ‘IoT box’ he’s developed to give his students a practical illustration of this fairly abstract concept.

What is the effect of Brexit on automation in the UK?

26 de setembro de 2019 Currently, workers from the EU have the right to travel and work freely across European borders. However, key statistics of net migration from the Office of National Statistics in the UK, show that net migration to the UK has been significantly reduced since 2016. With the announcement of Brexit, and the ensuing uncertainty around it, UK factories are perhaps no longer a viable destination for European workers.

Industry 4.0 - hot topic or hot air?

19 de setembro de 2019 Industry 4.0 is defined by Wikipedia as “the current trend of automation and data exchange in manufacturing technologies”. But what does that mean for you and your customers? And it isn’t really a new topic. At Omron, we’ve been working on manufacturing automation and data exchange for years.

How smart is your packaging line?

17 de setembro de 2019 Industry 4.0 is changing the way in which manufactured goods are produced, through the use of automation and data exchange. By incorporating it into your packaging line, you can start to enjoy a range of benefits, from better data management to improved efficiency. Moving to a modern, flexible and smart line will bring the most benefits, but replacing a complete production line might not be a viable option if you’re operating with tight margins. However, even small changes to your existing facilities can significantly boost your efficiency.

Smart sensing for multiple materials!

06 de maio de 2019 You know the routine. Switching from one product to another on your production line means a costly full stop, making all kinds of changes, starting up again, discarding the materials and packaging already fed into the line together with start-up rejects, and only then can production resume. Well, have we got good news for you: smart sensing for multiple materials!

Rock solid results with flexible production & robotics!

06 de maio de 2019 Today's market requires an increasingly agile production environment. Traditional industrial automation and robots are often too inflexible to successfully accomplish mass customization. Omron is enabling smart Industry 4.0 scenarios with a rare combination of intelligent automation solutions and robotics. Perfecting seamless human-robot collaboration and making more and more use of AI-driven possibilities, we assist manufacturers in realizing rock solid results with flexible production and robotics.

Direct link IT & OT puts factories on cloud nine

25 de fevereiro de 2019 Just imagine getting rid of cumbersome middleware or PC data concentrators at your production locations and being able to enjoy the benefits of direct database connectivity. Where Information Technology (IT) & Operational Technology (OT) come together something beautiful happens. We have created a production environment in which databases and machine controllers are best friends and keep in touch continuously.

Don't let vibrations catch you off balance!

25 de fevereiro de 2019 Machine operators are aware that sudden increases in vibrations or noise variations can herald a serious shake-up on their production lines. Unfortunately, it is hard for humans to quickly notice the indicators of, for instance, out-of-balance mechanics. The human touch is no match for dedicated sensors combined with high-speed Analogue Input Units that can reliably, precisely, and easily acquire synchronized data.

Expect the unexpected: Prepare, Prevent & Predict

25 de fevereiro de 2019 Sudden stops on a production line can cost a fortune. Avoiding unexpected stops and reducing scheduled downtime are key components to boost OEE. It sounds simple, but requires interpretation of the right, often complex, data. Artificial intelligence can optionally be deployed to interpret the collected relevant device and machine data real-time. Our solutions assist you to actively steer your operations to optimize the schedule for maintenance activities, and minimize maintenance and support costs.

Transforming the manufacturing industry beyond OEE

11 de fevereiro de 2019 Omron's series of 'OEE & me'-publications offers manufacturers, machine builders, and system integrators a convenient, complete and up-to-date guide to state-of-the-art OEE solutions. Practical insights that clearly explain what these new industrial automation solutions can do for your business. We will focus on topics like Staying Competitive (machine condition monitoring, autonomous production flows, and machine stops), Quality Control & Regulations (perfect packaging, managing waste, and avoiding contamination), and Mass Customization (avoiding idle time and production disruptions).