NJ5

Controlador Sysmac – Série NJ5

A série NJ5 é um controlador de máquinas para sequência lógica e motion que inclui opções de CPU para funções avançadas, tais como robótica e ligação às bases de dados.

- Tempo de ciclo mais rápido: 500 µs

- Número de eixos: 64, 32, 16

- Núcleo de motion sincronizado

- Funções: sequência lógica, motion, CNC, robótica, ligação à base de dados, SECS/GEM e OPC-UA

- Na versão 2.0, a ligação directa à base de dados foi alargada com as chamadas de procedimento armazenadas e a funcionalidade de comunicações seguras

- Ligação directa à base de dados: cliente SQL para servidor Microsoft SQL, Oracle, IBM DB2, MySQL, Firebird, PostgreSQL

- Controlo de robôs Delta, SCARA e Cartesianos

- Funcionalidade de CNC: Ideal para tornos, máquinas fresadoras ou corte XY, bem como qualquer outra aplicação de seguimento de percurso, tais como máquinas de distribuição, dobragem, desbaste e moldagem

- Capacidade para efectuar múltiplas tarefas

- Portas EtherCAT e EtherNet/IP incorporadas

- A topologia em anel EtherCAT é suportada para manter as comunicações e o controlo em caso de uma falha no dispositivo ou um cabo danificado

Especificações e info encomendas

| Produto | Max. number of synchronous axes | Supports DB connection | Supports SECS/GEM | Supports CNC | Primary task cycle time | Program memory | Variables memory | Communication port(s) | Max. number of remote I/O nodes | Supports sequence control | Supports motion control | Supports robotics control | Max. number of robots | Descrição | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

16 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller 16 Ejes |

|

|

|

16 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller + Cliente SQL 16 Ejes |

|

|

|

16 | No | Yes | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU with SECS/GEM communication, 20MB memory, built-in EtherCAT (16 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP. |

|

|

|

32 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller 32 Ejes |

|

|

|

32 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller + Cliente SQL 32 Ejes |

|

|

|

64 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller 64 Ejes |

|

|

|

64 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | NJ501 Machine Controller + Cliente SQL 64 Ejes |

|

|

|

16 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 4 | NJ501 Machine Controller + Robotics + Cliente SQL 16 Ejes |

|

|

|

32 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 8 | NJ501 Machine Controller + Robotics 32 Ejes |

|

|

|

64 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 8 | NJ501 Machine Controller + Robotics 64 Ejes |

|

|

|

32 | No | No | Yes | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | CPU NJ5 Sysmac CNC, 20 MB de memoria, EtherCAT (32 servo-ejes, 192 nodos EtherCAT en total) y EtherNet/IP Licencia USB no incluida. |

|

Precisa de ajuda?

Estamos aqui para ajudar! Contacte-nos e os nossos especialistas irão ajudá-lo a encontrar a melhor solução para a sua empresa.

Contactar NJ5

Obrigado por ter feito o seu pedido. Entraremos em contacto consigo logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

DownloadOrçamento para NJ5

Através deste formulário pode pedir um orçamento para o produto que escolheu. Por favor complete os campos marcados com *. Os seus dados serão tratados confidencialmente.

Obrigado por ter pedido uma cotação. Enviaremos a respectiva informação logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

DownloadEtherCAT Redundancy

A redundância minimiza os períodos de inactividade

Mesmo que uma parte da rede EtherCAT esteja desligada, a redundância de cabos proporciona uma conectividade contínua.

Esta função permite resolver o corte de ligação sem parar as máquinas e a linha de produção, sendo que um controlador possibilita o controlo tanto da máquina como da segurança.

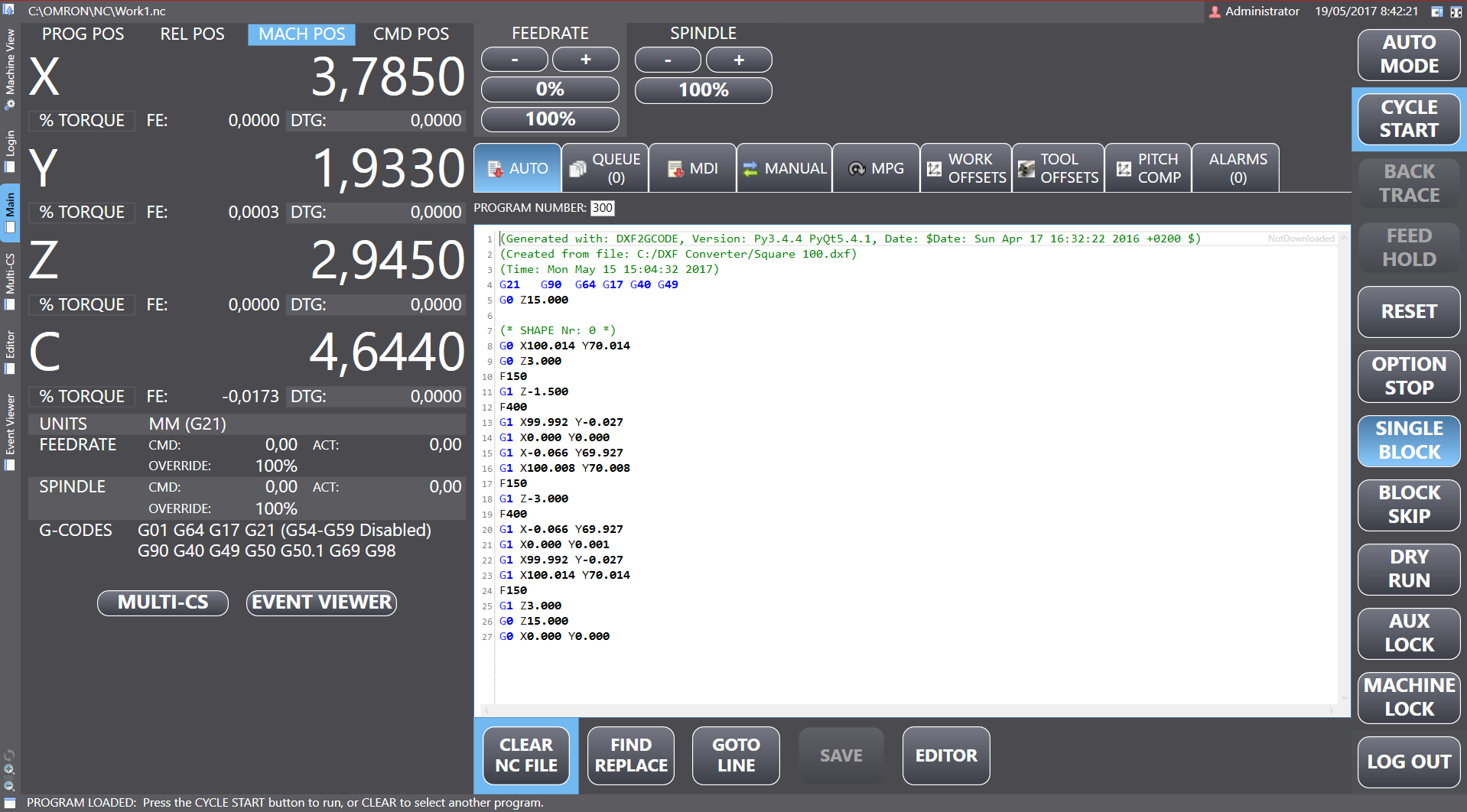

Software

Sysmac Studio - Ambiente de desenvolvimento integrado

- Uma ferramenta única para sequência lógica, motion, segurança, robótica, visão, HMI e ligação à bases de dados

- Conformidade com a norma IEC 61131-3

- Sysmac Library para optimizar o tempo dedicado à engenharia e a disponibilidade das máquinas

- Editor de ficheiros de código G

- Monitor activo de execução e visualização de código G/M

- Terminal de comandos

- Jogging, regresso à posição inicial

- O software personalizável permite a adição de funcionalidades pelos utilizadores (requer a versão de SDK de operador de CNC)

Vídeos

-

OMRON Sysmac Platform with CNC

Our Sysmac Platform now integrates the complete machine processes and CNC in one machine controller. It improves production efficiency, enables complex motion trajectories and reduces machine development environment.

03:17

OMRON Sysmac Platform with CNC

Our Sysmac Platform now integrates the complete machine processes and CNC in one machine controller. It improves production efficiency, enables complex motion trajectories and reduces machine development environment.

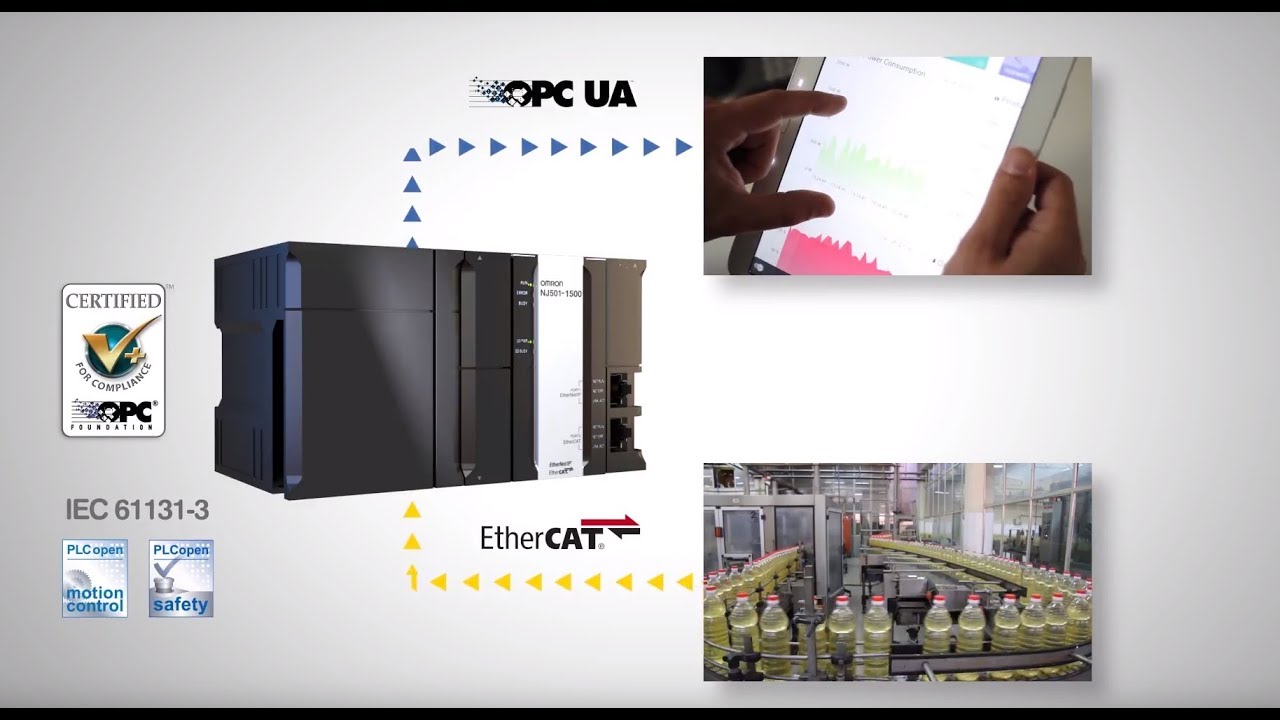

OMRON NJ5 Controller with OPC UA

Omron implements OPC UA as a standard feature.Produtos relacionados

-

Séries XS5/XS2/XS6

-

Para aplicações que requerem processamento de alta velocidade para controlo de máquinas, segurança, fiabilidade e manutenção.

-

Servomotor Sysmac para uso geral

-

Maior produtividade e ambiente mais seguro

-

Segurança integrada em automação de máquinas

-

Acesso remoto seguro e simples para as suas máquinas

-

Aumente a sua produtividade

-

Série NA – A HMI do Sysmac

-

Desempenho e viabilidade para controlo de máquinas

-

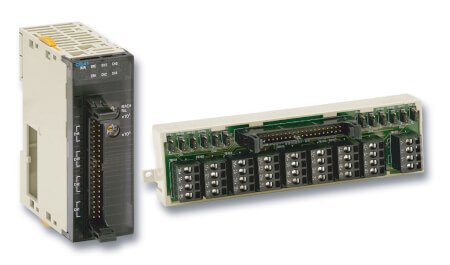

8 a 64 pontos por unidade - entrada, saída ou misto

-

Aberta a qualquer comunicação

-

Adiciona controlo de movimento a qualquer PLC de CJ

-

Da E/S analógica básica ao controlo de temperatura avançado

Downloads

Inicie sessão ou registo ao conteúdo desta página

Inicie sessão ou registo ao conteúdo desta página

_cg_en.jpg)

Inicie sessão ou registo ao conteúdo desta página

_cg_en.jpg)

-ect_vision_sensor_cg_en.jpg)

_cg_en.jpg)

_ac58-series_absolute_encoder_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

-x)_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)