Câmaras FH

Portfólio da câmara de visão FH – a câmara certa para responder a qualquer aplicação

Esta gama de produtos representa a gama completa de câmaras de leitura da área para responder a qualquer aplicação em qualquer indústria de visão industrial. Câmaras em miniatura extremamente compactas com iluminação integrada e conjunto completo de câmaras C-mount e M42-mount até 21 megapixéis. Tudo com a possibilidade de ligação ao potente controlador de visão FH/FZ5, basta ligar e reproduzir.

-

Vision System FH series

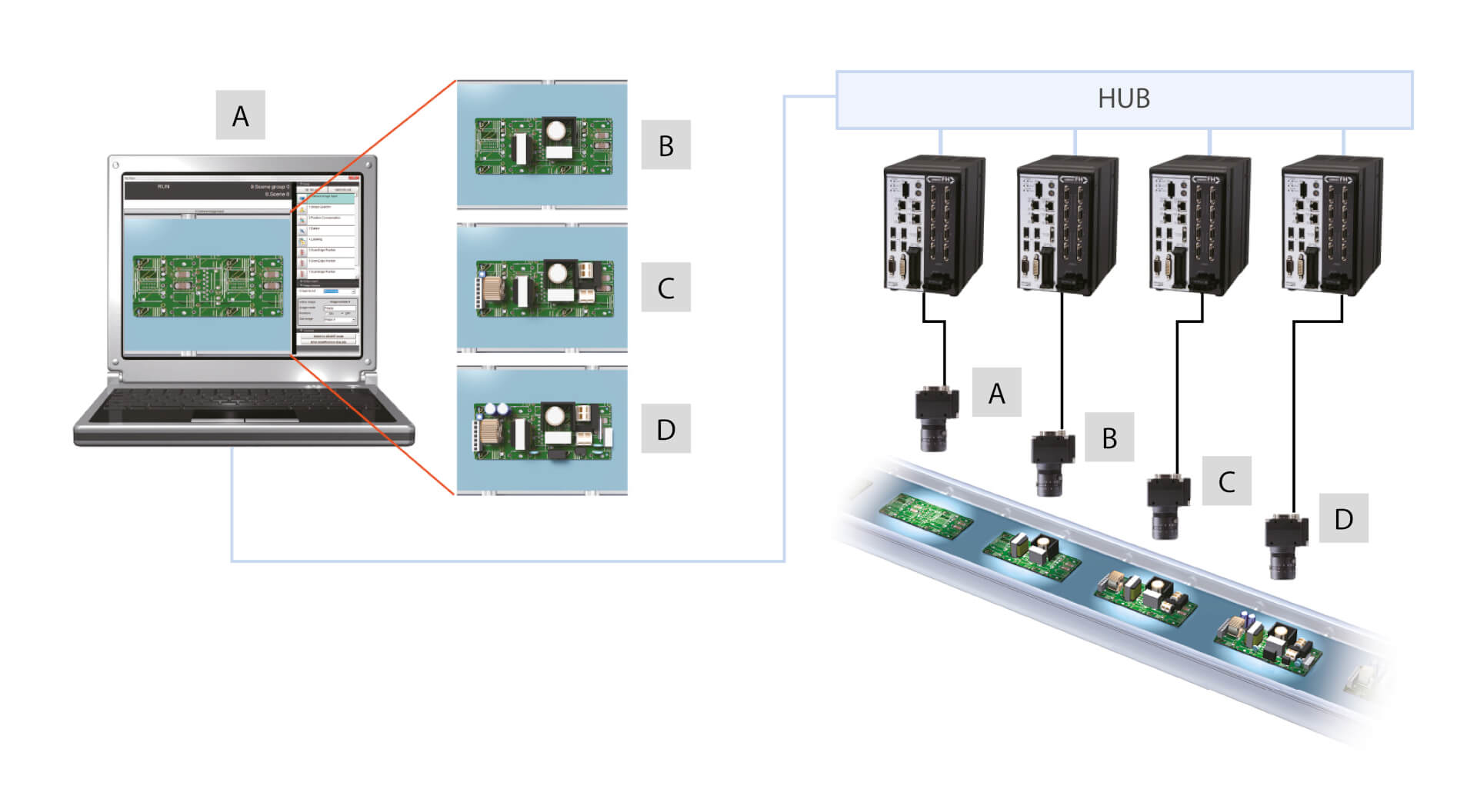

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.Uma gama completa de câmaras para várias aplicações

Novo sistema de visão FH com a primeira tecnologia de IA para detecção de defeitos da indústria

O sistema de processamento de imagens identifica defeitos subtis com sensibilidade semelhante à do ser humano para taxas de detecção de defeitos mais elevadas.

Características

Uma gama completa de câmaras para várias aplicações

Funcionamento mais rápido da máquina

Integração fácil de software e hardware

Tecnologia de detecção de velocidade ultra-elevada num design compacto

Câmaras inteligentes FH/FZ concebidas para utilização em todos os tipos de inspecção de objectos, operações de medição e posição/orientação. Esta câmara compacta e o sistema de controlo são facilmente integrados em quase todas as máquinas ou robôs. O sistema é excepcionalmente capaz de fornecer um rendimento de trabalho mais rápido e preciso para lhe proporcionar maior eficiência, custos reduzidos e muito mais.

Funcionamento ideal tanto online como offline

As ligações a uma unidade de disco rígido de rede ou a um computador de rede permitem uma vasta gama de possibilidades de funcionamento. Pode registar imagens de medição a longo prazo, ou pode efectuar verificações e ajustes num computador sem parar a série FH.

Soluções de iluminação inovadoras

- A luz MDMC permite-lhe alterar livremente a cor e o padrão de direcção em milissegundos. Pode escolher o melhor padrão ao combinar direcções de iluminação, RGB a cores e 128 níveis de brilho de 13 blocos

- Não é necessário trocar o hardware durante as alterações de produto.

- Melhore a funcionalidade de inspecção que procura – fácil, rápida e fiável

- Combine centenas de iluminadores numa só unidade

- A luz PMS permite que o seu sistema de visão detecte o que apenas o instrumento óptico mais inteligente, o olho humano, é capaz de reconhecer

- Aumenta a taxa de inspecção visual automática – fiável, repetível e produtiva

- Cria as soluções de inspecção visual mais robustas, mesmo em superfícies extremamente difíceis

O sistema de visão FH é compatível com os protocolos de comunicação mais modernos, rápidos e amplamente aceites pela indústria – agora também ProfiNet

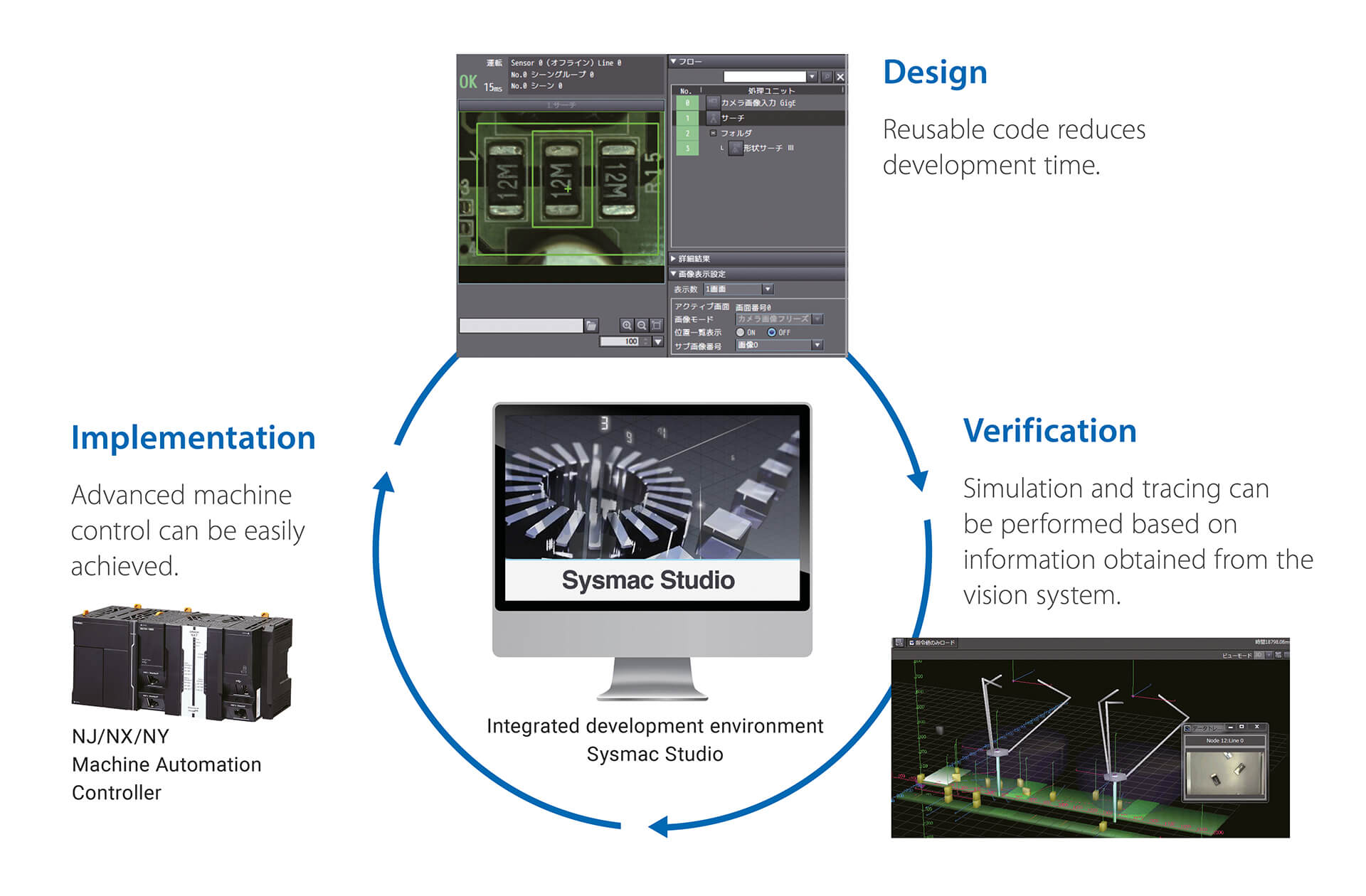

Aproveitando os benefícios da plataforma Sysmac da OMRON, a integração de um sistema de visão na sua máquina nunca foi tão fácil. Não sabemos apenas como inspeccionar o seu produto, também podemos transportá-lo, controlá-lo e conceber a solução completa em função do seu processo e produção. Quer estejamos a ajudá-lo a efectuar uma inspecção única ou a controlar uma linha de produção completa, em todas as etapas a nossa atenção reside numa arquitectura clara e compreensível para tornar a sua vida mais fácil e melhorar a produtividade.

-

1DesignO código reutilizável reduz o tempo de desenvolvimento.

-

2VerificaçãoA simulação e o rastreamento podem ser efectuados com base nas informações obtidas a partir do sistema de visão.

-

3ImplementaçãoO controlo avançado da máquina pode ser facilmente alcançado.

Aplicações

Indústria automóvel

- Linhas de montagem

- Linhas de inspecção de controlo de qualidade

- Inspecção estética

- Aplicações de medição de alta precisão

Alimentação e mercadorias

- Inspecção de qualidade

- Linhas de enchimento de líquido/pó

- Embalagem secundária primária

- Pick and place

Efeitos de rastreabilidade

- Impressão e inspecção de etiquetas

- Aplicações para rastreamento

Vídeos

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

04:37

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

Connector Inspection Function | FH-series Vision System and Cameras

The OMRON Connector Inspection Function in the FH-series integrates settings required for pin position detection and allows users to perform complicated dimensional inspections like coplanarity inspection just by selecting inspection items. A search model can be shared between different types of connectors, reducing configuration time when new types are added. Just change the number if inspection areas for connectors with different numbers of pins to complete adjustment. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

03:56

Connector Inspection Function | FH-series Vision System and Cameras

The OMRON Connector Inspection Function in the FH-series integrates settings required for pin position detection and allows users to perform complicated dimensional inspections like coplanarity inspection just by selecting inspection items. A search model can be shared between different types of connectors, reducing configuration time when new types are added. Just change the number if inspection areas for connectors with different numbers of pins to complete adjustment. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Filter | FH-series Vision System

OMRON is using artificial intelligence to reproduce the visual sensitivity and experience of human inspectors. The AI filter detects scratches with human-like sensitivity. Using an AI filter equipped with defect extraction technology, only the points that are estimated to be scratches with be automatically extracted. The AI algorithms extract the scratch itself, rather than the definition based on colour and brightness. This makes defect detection much more stable flaw. The AI filter eliminates missed defects and AI Fine Matching avoids overdetection almost entirely. No special environment construction or expertise required. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

03:03

AI Filter | FH-series Vision System

OMRON is using artificial intelligence to reproduce the visual sensitivity and experience of human inspectors. The AI filter detects scratches with human-like sensitivity. Using an AI filter equipped with defect extraction technology, only the points that are estimated to be scratches with be automatically extracted. The AI algorithms extract the scratch itself, rather than the definition based on colour and brightness. This makes defect detection much more stable flaw. The AI filter eliminates missed defects and AI Fine Matching avoids overdetection almost entirely. No special environment construction or expertise required. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Especificações e info encomendas

| Produto | Number of pixels | Focus distance | Autofocus | Camera family | Camera type | Frame rate | Illumination | Image width | Image height | Scan type | Shutter type | Image sensor format | Image sensor type | Lens mount | Lens type | Pixel size | Degree of protection (IP) | Descrição | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

2.0 MP | No | FH | Color | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Cámara FH color Alta resolución 2Mp |

|

|

|

|

4.0 MP | No | FH | Color | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Cámara FH color Alta resolución 4Mp |

|

|

|

|

5.0 MP | No | FH | Color | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Cámara FH color Alta resolución 5Mp Rolling Shutter |

|

|

|

|

20.4 MP | No | FH | Color | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | Cámara FH, alta velocidad, 20,4 megapíxeles, montaje en C, obturador giratorio, color |

|

|

|

|

0.4 MP | No | FH | Color | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | Cámara FH, alta velocidad, 0,4 megapíxeles, montaje en C, obturador global, color |

|

|

|

|

1.6 MP | No | FH | Color | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | Cámara FH, alta velocidad, 1,6 megapíxeles, montura C, obturador global, color |

|

|

|

|

3.2 MP | No | FH | Color | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | Cámara FH, alta velocidad, 3,2 megapíxeles, montura C, obturador global, color |

|

|

|

|

5.0 MP | No | FH | Color | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | Cámara FH, alta velocidad, 5 megapíxeles, montaje en C, obturador global, color |

|

|

|

|

12 MP | No | FH | Color | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | Cámara FH, alta velocidad, 12 megapíxeles, montura C, obturador global, color |

|

|

|

|

0.3 MP | No | FH | Monochrome | 308 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | CMOS | C-mount | Not Applicable | 7.4 µm | IP10 | Cámara FH monocromo Estándar 640x480 |

|

|

|

|

2.0 MP | No | FH | Monochrome | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Cámara FH monocromo Alta resolución 2Mp |

|

|

|

|

4.0 MP | No | FH | Monochrome | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Cámara FH monocromo Alta resolución 4Mp |

|

|

|

|

5.0 MP | No | FH | Monochrome | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Cámara FH monocromo Alta resolución 5Mp Rolling Shutter |

|

|

|

|

20.4 MP | No | FH | Monochrome | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | Cámara FH, alta velocidad, 20,4 megapíxeles, montaje en C, obturador giratorio, monocroma |

|

|

|

|

0.4 MP | No | FH | Monochrome | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | Cámara FH, alta velocidad, 0,4 megapíxeles, montaje en C, obturador global, monocromo |

|

|

|

|

0.3 MP | No | FH | Monochrome, SWIR | 240 fps | None | 640 pixels | 512 pixels | Area scan | Global | 1/4" | IMX991 | C-mount | Not Applicable | 5.0 µm | IP40 | Cámara FH SWIR, 0.3 MPixel, montaje en C, obturador global, monocroma |

|

|

|

|

1.6 MP | No | FH | Monochrome | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | Cámara FH, alta velocidad, 1,6 megapíxeles, montaje en C, obturador global, monocroma |

|

|

|

|

1.3 MP | No | FH | Monochrome, SWIR | 120 fps | None | 1280 pixels | 1024 pixels | Area scan | Global | 1/2" | IMX990 | C-mount | Not Applicable | 5.0 µm | IP40 | Cámara FH SWIR, 1.3 MPixel, montaje en C, obturador global, monocroma |

|

|

|

|

3.2 MP | No | FH | Monochrome | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | Cámara FH, alta velocidad, 3,2 megapíxeles, montaje en C, obturador global, monocroma |

|

|

|

|

5.0 MP | No | FH | Monochrome | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | Cámara FH, alta velocidad, 5 megapíxeles, montaje en C, obturador global, monocroma |

|

Estamos aqui para ajudar

Tem alguma dúvida? Os nossos especialistas estão disponíveis para ajudar em todas as etapas.

Contactar Câmaras FH

Obrigado por ter feito o seu pedido. Entraremos em contacto consigo logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

DownloadOrçamento para Câmaras FH

Através deste formulário pode pedir um orçamento para o produto que escolheu. Por favor complete os campos marcados com *. Os seus dados serão tratados confidencialmente.

Obrigado por ter pedido uma cotação. Enviaremos a respectiva informação logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

DownloadTransferências

Produtos relacionados

Precisa de ajuda?

Estamos aqui para ajudar! Contacte-nos e os nossos especialistas irão ajudá-lo a encontrar a melhor solução para a sua empresa.

Contactar Câmaras FH

Obrigado por ter feito o seu pedido. Entraremos em contacto consigo logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

DownloadOrçamento para Câmaras FH

Através deste formulário pode pedir um orçamento para o produto que escolheu. Por favor complete os campos marcados com *. Os seus dados serão tratados confidencialmente.

Obrigado por ter pedido uma cotação. Enviaremos a respectiva informação logo que possível.

Temos experienciado dificuldades técnicas. O seu pedido não foi submetido com sucesso. Por favor aceite as nossas desculpas e tente novamente mais tarde. Detalhes: [details]

Download

_instruction_sheet_en.jpg)

_-_image_processing_system_instruction_sheet_en.jpg)